Quick Guide to Flame Retardant 3D Printing Filaments on Zortrax Endureal 3D Printer

Summary

- Zortrax Endureal supports 3D printing with a wide range of flame-retardant 3D printing filaments.

- BASF Ultrafuse® PPSU is a high-performance flame-retardant polymer compliant designed for railway applications while Z-PEI 9085 is made for aerospace industry.

- BASF Ultrafuse® PC/ABS FR and Nanovia PC-ABS V0 are affordable flame-retardant materials that can be used where going for more expensive high-performance polymers is not necessary.

Certified flame retardancy is often one of the key features required of 3D printing materials in industries such as aerospace or railroad. 3D printed parts that are to be fitted in aircraft interiors or railcars have to be safe for passengers and there are various certification procedures to make sure that it is indeed the case. Here you can learn which 3D printing materials compatible with the Zortrax Endureal, an industrial 3D printer designed for most challenging applications, are best for aerospace and railroad applications and why.

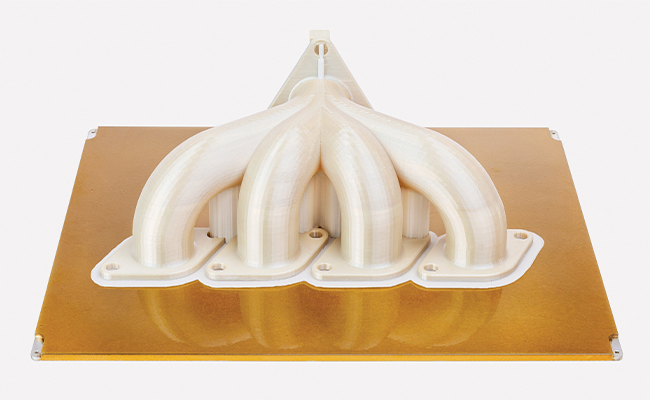

Zortrax Endureal 3D printer works with a wide range of flame-retardant 3D printing materials.

Z-PEI 9085 Aerospace 3D Printing Material

Z-PEI 9085 is a high-performance 3D printing filament used in aerospace for printing aircraft interior components and in space industry, as it can withstand low earth orbit environment. Given the profile of its target customers, it is one of the most thoroughly tested materials in Zortrax range. It has passed NASA and ESA outgassing tests which means it does not release gasses during thermal vacuum cycling tests. It is also inherently flame retardant. All this comes with excellent strength-to-weight ratio achievable in 3D printed parts, which is comparable to metal alloys. The widely accepted flame retardancy norms that Z-PEI 9085 is compliant with are as follows:

- UL 94 V0 flammability rating

- FAR 25.853

To achieve the V0 rating a sample must pass a vertical burn test. This test is considered passed if the material extinguishes on its own within 10 seconds after the flame was applied to the bottom of a vertically oriented sample. The test is repeated two times.

FAR 25.853 is an american FIA standard flammability test for materials used in aircraft interiors. Its European counterpart is called CS 25.853 and in China the same standard is known as CCAR 25.853. The testing procedure here is a bit more specific. It is performed in the flammability chamber and consists or a series of tests including:

- Vertical flammability test with the fire being applied for 12 seconds

- Vertical flammability tests with the fire being applied for 60 seconds

- Horizontal flammability test with the fire being applied for 15 seconds

Z-PEI samples extinguished in under 2 seconds in the 12 seconds variant of the vertical flammability test and in under 3.6 seconds in the 60 seconds variant. In horizontal flammability tests, the samples did not invite and consistently scored 0 in average burn rate. This, in combination with excellent Flame Smoke Toxicity (FST) results, means that Z-PEI 9085 is safe to use in aerospace interiors. Since railroad flammability standards are often similar to the ones used in aerospace, Z-PEI 9085 can also be used in railroad applications upon prior certification by the customer.

BASF Ultrafuse® PPSU Railroad 3D Printing Filament

BASF Ultrafuse® PPSU is a high-performance material developed by BASF, one of the largest chemical companies in the world, specifically for extrusion-based 3D printing in railroad applications. This 3D printing filament passed numerous fire tests in accordance with the EN 45545-2 European railway standard.

The way the EN 45545-2 standard works is a bit more complex than the UL 94 norm. There are 28 different requirements, each coming with an assigned group of tests. Performance in those tests has three grades corresponding to the three fire hazard levels. Each product category in a railroad industry has a list of necessary requirements and a specified fire hazard level. Sounds a bit mind-boggling but it really isn’t once you get the grasp of it. Here’s how it works with BASF Ultrafuse® PPSU.

Vertical burn test with BASF Ultrafuse PPSU sample 3D printed on Zortrax Endureal.

BASF Ultrafuse® PPSU has been cleared at all three hazard levels in the following requirements:

- Requirement 7 (R7)

- Requirement 23 (R23)

- Requirement 24 (R24)

- Requirement 26 (R26)

The first requirement on this list, the R7, states that a material has to pass four tests to qualify:

- A lateral flame spread test in accordance with the ISO 5658-2 procedure

- A heat release rate test in accordance with the ISO 5660-1 procedure

- A smoke density test in accordance with the ISO 5659-2 procedure

- An FTIR toxicity gas analysis test in accordance with the EN 17084 procedure.

Then, the criteria for the hazard levels are specified for each test. For example, a gas toxicity test (the last one on the list above) is aimed at establishing the conventional index of toxicity (CITg). Maximum CITg at each hazard levels is as follows:

- No maximum level at the first fire hazard level (HL1)

- 1.8 CITg at the second fire hazard level (HL2)

- 1.5 CITg at the third fire hazard level (HL3)

BASF Ultrafuse® PPSU had CITg measured at 0.17, and qualified for all fire hazard levels with a healthy margin.

All this determines what railway components you can or can’t 3D print with BASF Ultrafuse® PPSU on the Zortrax Endureal 3D printer. You just find the category of the part you need to print and see what the necessary requirements are. For example, meeting the requirement 7 discussed above is necessary for the product categories such as IN12C, which includes air ducts on locomotives or EX5, which covers external design features like flaps, grilles, or streamlining parts. These all can be successfully 3D printed with BASF Ultrafuse® PPSU. Just remember to dry the BASF Ultrafuse® PPSU filament in 125 °C for 8 hours before printing and to cover the Endureal’s build platform with Magigoo HT glue to achieve optimal adhesion.

If this seems like too much, go ahead and get in touch with our Sales Team. They’ll be happy to discuss your specific case with you and offer the optimal solution.

BASF Ultrafuse® PC/ABS FR Affordable Railroad Filament

BASF Ultrafuse® PC/ABS FR is a flame retardant blend of polycarbonate and acrylonitrile butadiene styrene. It also complies with the EN 45545-2 railway standard and meets the requirement 26 (R26) at all three fire hazard levels. This means that the material passed the vertical small flame test in accordance with the EN 60695-11-10 procedure which is nearly identical to the one used in the UL 94 standard. In railroad industry the R26 is necessary for 3D printing small electrotechnical products (the EL10 category) such as contactors, switches, or low power circuit breakers.

While this 3D printing material has way more limited applications than the BASF Ultrafuse® PPSU, it is also more affordable and can be used for parts working in less challenging applications, where going for high-performance polymers is not necessary.

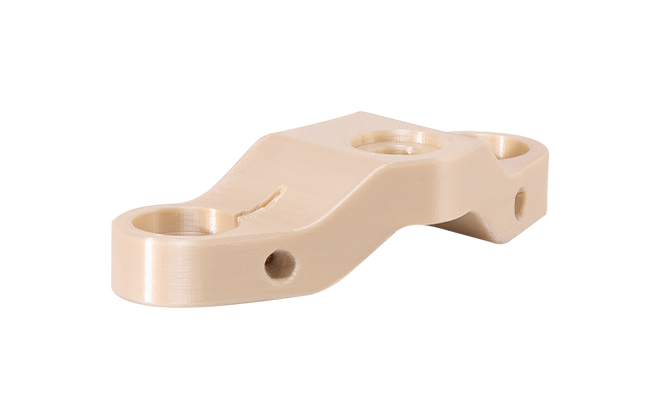

Flame retardant LED lamp mounting 3D printed with BASF Ultrafuse PC/ABS FR on Zortrax Endureal.

Nanovia PC-ABS V0 Budget-Friendly Flame-Retardant Material

The most affordable of flame-retardant 3D printing materials compatible with Zortrax Endureal 3D printer is Nanovia PC-ABS V0. It has the UL94 V-0 rating and can be used for printing functional prototypes that are to operate in conditions with increased fire risk or for end-use parts that do not require compliance with industry-specific standards like FAR 25.853 or EN 45545-2.

The material is easy to print and has decent shock-resistance.

What Makes Zortrax Endureal Great for Flame-Retardant Materials

Zortrax Endureal is an industrial 3D printer which can work with all four flame-retardant 3D printing materials covered above. With large workspace and excellent quality-to price ratio, the Endureal is a flexible additive manufacturing tool that can work with top-end filaments like BASF Ultrafuse® PPSU or Z-PEI 9085. It can also process more affordable materials like BASF Ultrafuse® PC/ABS FR and Nanovia PC-ABS V0, which are a more budget-friendly choice for less demanding applications.

The printer has a closed printing chamber that guarantees optimal printing conditions throughout the entire 3D printing process, advanced safety systems compliant with health and safety regulations in the EU and the USA, and ability to work with metals which comes in handy when even the strongest polymer filaments prove too weak.

Get in touch with our Sales Team: sales@zortrax.com if you wish to know more about the Zortrax Endureal 3D printer. Of course, you can also just go straight ahead and order it now through Zortrax Online Store.