How to Get Perfect 3D Prints with BASF Ultrafuse® PPSU on Zortrax Endureal

Summary

- Best 3D printing results with BASF Ultrafuse® PPSU on the Zortrax Endureal 3D printer is a simple process.

- Following guidelines explained in this post guarantees getting the most out of the BASF Ultrafuse® PPSU filament.

- The following sections explain how to handle BASF Ultrafuse® PPSU spools, how to prepare the Endureal printer for work, and how to choose the correct printing settings.

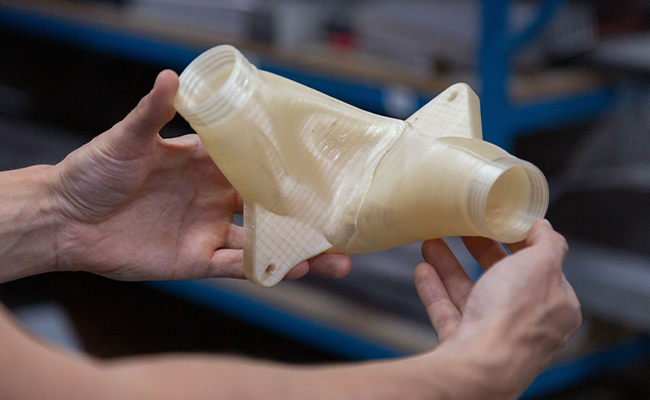

BASF Ultrafuse® PPSU is a high-performance, flame-retardant 3D printing filament designed for railway applications and compliant with the European EN 45545-2 standard. Here is a simple guide to using this extraordinary polymer to its full potential on the Zortrax Endureal industrial 3D printer.

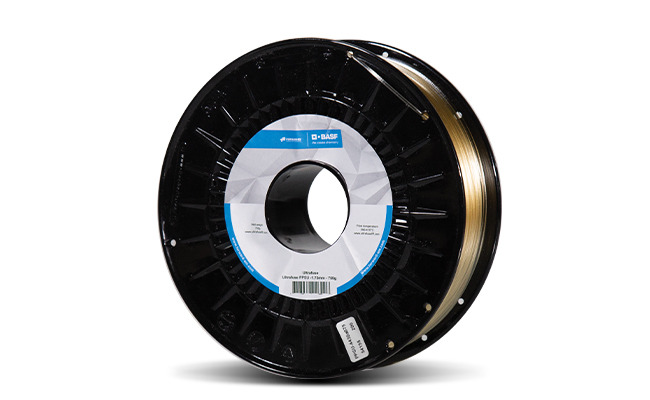

How to Store BASF Ultrafuse® PPSU Spools

Successful 3D printing with BASF Ultrafuse® PPSU begins with storing the material properly. Before first use, it is best to keep the filament in its original packaging at room temperature. Later on, after the printing process is done, the spool should be removed from the Zortrax Endureal 3D printer and kept in a place with limited exposure to sunlight and moisture.

BASF Ultrafuse® PPSU spools have to be stored in dry conditions without exposure to sunlight.

To make sure the BASF Ultrafuse® PPSU filament spool is in perfect condition for future prints, it is best to use vacuum packaging for storage.

How to Prepare BASF Ultrafuse® PPSU Spool for 3D Printing

Even if the spool was stored properly, it should always be dried before loading it into the Zortrax Endureal 3D printer. The reason why this step is so important is that moisture absorbed by the material evaporates when the material is heated in the extrusion process. Resulting steam creates tiny bubbles in the 3D printed part which can compromise its geometry and mechanical properties. Zortrax recommends two, alternative drying procedures:

- Drying process can be performed in the printing chamber of the Zortrax Endureal 3D printer. Recommended settings are 48 hours of drying at 120 °C.

- Drying process can be also performed in a vacuum dryer. While using the vacuum dryer, the drying temperature can be set to 125 °C and the duration to 8 hours.

Drying BASF Ultrafuse® PPSU filament before printing is necessary to achieve accurate geometry and optimal mechanical properties of 3D printed parts.

Using dedicated drying devices is generally faster and does not occupy the Endureal 3D printer which can be used for other projects. If the dedicated drying device is not available, however, the drying procedure performed in the Endureal itself is just as effective, albeit significantly longer. Either way, the spool of BASF Ultrafuse® PPSU 3D printing filament should be loaded into the Endureal 3D printer immediately after the drying process is done.

How to Prepare Zortrax Endureal 3D Printer for BASF Ultrafuse® PPSU

Once the BASF Ultrafuse® PPSU 3D printing filament spool is loaded into the Zortrax Endureal 3D printer, the build platform has to be covered with Magigoo HT glue to ensure proper adhesion of the material. Skipping this step may result in prints failed due to the material rolling up from the build platform which usually compromise the model geometry beyond recovery, and in extreme cases, can damage the Endureal’s extruder’s module.

The Endureal’s build platform has to be covered with Magigoo HT glue to ensure proper adhesion of the BASF Ultrafuse® PPSU filament.

It is also important to follow all standard maintenance guidelines for the Zortrax Endureal 3D printer such as cleaning the printing chamber and emptying the waste container before every printing session.

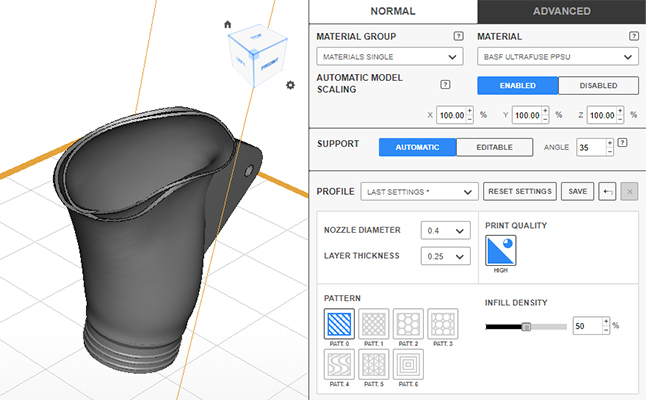

What Are the Best Printing Settings for BASF Ultrafuse® PPSU

When the BASF Ultrafuse® PPSU 3D printing filament is loaded to the Endureal 3D printer and the build platform is covered with the Magigoo HT glue, the next step is choosing the right printing settings. Z-SUITE slicer, which is a 3D printing software that comes free with every Zortrax 3D printer, has a large portfolio of predefined printing profiles for each supported 3D printing filament.

Z-SUITE software has a predefined 3D printing profile with throughly tested settings for BASF Ultrafuse® PPSU filament.

These profiles are thoroughly tested by Zortrax engineers and guarantee best possible printing results. BASF Ultrafuse® PPSU also has its predefined printing profile in Z-SUITE and it is highly recommended to use it when printing with this filament.

Why Zortrax Endureal is the Best 3D Printer for BASF Ultrafuse® PPSU

Zortrax Endureal is an industrial 3D printer with large workspace and excellent quality-to price ratio. It is a flexible additive manufacturing tool that can work with multiple high-end filaments like BASF Ultrafuse® PPSU. It can also process more affordable materials like BASF Ultrafuse® PC/ABS FR and Nanovia PC-ABS V0, which are a more budget-friendly choice for less demanding applications.

Zortrax Endureal 3D printer works with a wide range of flame-retardant 3D printing materials.

The printer has a closed printing chamber that guarantees optimal printing conditions throughout the entire 3D printing process, advanced safety systems compliant with EU and US health and safety regulations and is even capable of 3D printing metal parts when the strongest polymer filaments prove too weak for the job.

Contact Zortrax Sales Team at sales@zortrax.com to learn more about how Zortrax Endureal 3D printer and BASF Ultrafuse® PPSU filament can improve the workflows at your business.