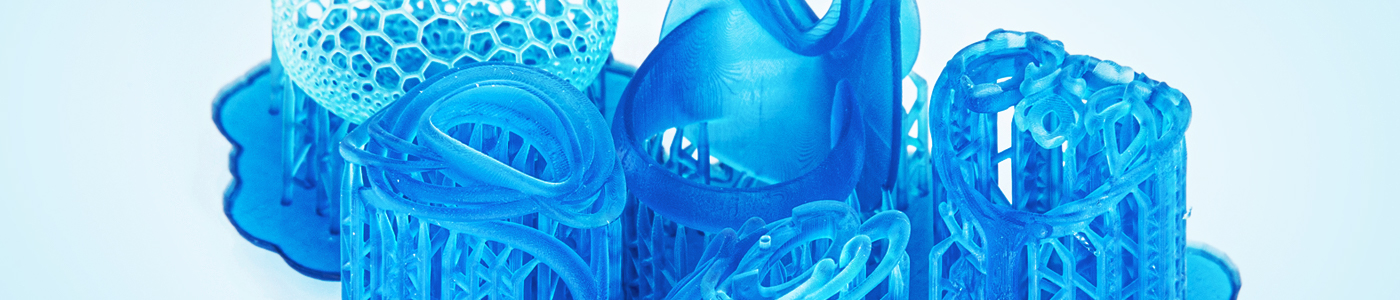

Precise castable 3D printing resin designed for jewelry casting. It’s a functional equivalent of wax used in the investment casting and can be processed with the same toolset. BlueCast X5 has excellent dimensional accuracy, burnout properties with 0.00% ash residue. Sublimation starts at 130° C.

The resin can be used for fast burnouts at recommended temperature of 850° C. Does not contain harmful chemicals that could potentially contaminate the investment. Models 3D printed with BlueCast X5 do not need further curing which makes the jeweler’s workflow easier and faster. Overall, this resin guarantees very high direct casting quality with any kind of investment.

*The resin can lose color when exposed to UV light. It is completely normal and does not affect its specified properties.