Beyond prototyping

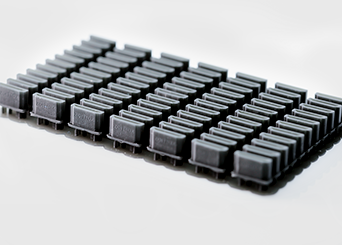

Bridge manufacturing begins when the prototyping stage is done. A cluster of 3D printers is employed to print functional products in the same way they printed the final prototype.

Precise resin 3D printers become more and more integrated into product development processes in consumer electronics. They are efficient prototyping and production tools that can produce shapes unattainable with injection molding technology which designers can use to make truly innovative devices.

In modern consumer electronics utility is just as important as captivating design. Resin 3D printers can help achieve both. Their speed and precision allow to cost-effectively iterate through multiple concepts util the perfect balance of form and function is reached. And then they can be used for manufacturing the first short series of fully functional products to bridge the gap between the prototyping stage and going into mass production.

Small, intricate parts are critical to modern consumer electronics and printing such parts is what resin 3D printers are made for.

Businesses can cost-effectively build prototypes that can be put together up to a standard comparable with mass manufactured products.

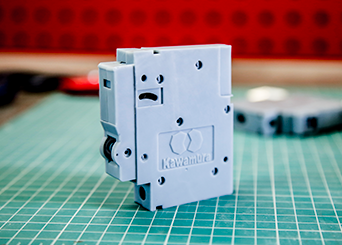

Resin 3D printers are precise enough to ensure the quality of parts like remote controllers is on par with mass produced items without additional costs.

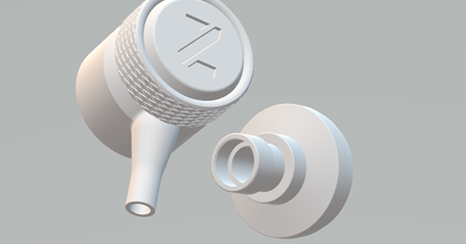

Tight fit possible to achieve with resin 3D printed parts is crucial to get the prototypes' ergonomics on par with final products.

Resin 3D printers can print small parts with complex internal architecture like the one necessary to make earpieces with good acoustics.

Bridge manufacturing smoothens the transition from prototyping to production. Ordering injection molds and setting up the rest of a traditional manufacturing line is a heavy investment, especially for small and medium scale businesses. Instead, a farm of resin 3D printers can be used to manufacture the first short series of the new product. This way, the 3D printers work to generate income and mitigate risks as the design, at this stage, can still be adjusted cost-free.

Bridge manufacturing begins when the prototyping stage is done. A cluster of 3D printers is employed to print functional products in the same way they printed the final prototype.

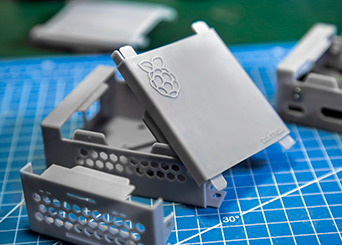

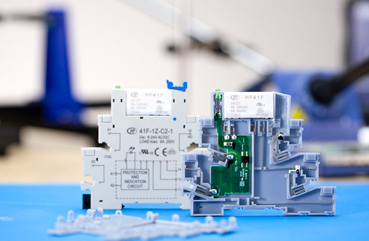

Once the particular PCBs and wiring layout is chosen, an appropriate casings and other parts designed to hold them in place can be 3D printed to build the first conceptual model and all its further versions.

The initial series of the new product can be used to gather feedback from the market and adjust the design where necessary.

When the market feedback is good and there is a demonstrable demand for the product, a business can reinvest the revenue into setting up a mass manufacturing line.

From CAD/CAM design, through building the first conceptual model and rapid prototyping, to early stages of manufacturing, resin 3D printers have become widely used tools in consumer electronics design. Here's how a typical product development process looks like with resin 3D printers onboard.

Consumer products begin their life in a CAD/CAM design software. There are different programs for designing printed circuit boards (PCBs), electrical engineering, and for modeling the casings.

Once the particular PCBs and wiring layout is chosen, an appropriate casings and other parts designed to hold them in place can be 3D printed to build the first conceptual model and all its further versions.

3D printers used at the prototyping stage can produce the first short series of the new product meant either for beta-testing or for generating income which is then reinvested in scaling up to mass production.

Zortrax Inkspire is a resin UV LCD 3D printer with significant precision and speed. It works with 50x50 microns XY resolution and 25 microns minimal layer height which is enough to print small casings and other elements necessary for modern electronics. Because its LCD screen with UV LED backlighting cures each model's layer all at once, Zortrax Inkspire has up to 8x speed advantage over leading SLA 3D printers. That's why it can be easily scaled up to work in a 3D printing farm offering medium to large manufacturing output.

Four most important questions to ask when choosing a resin 3D printer for engineering in electronics are how precise it is, how fast it is, how well does it scale up, and how effective it is in supporting early stages of manufacturing. Zortrax Inkspire is better than a leading SLA 3D printer in all those areas.

Z-SUITE is a dedicated slicing and 3D printing farm management software that comes free with every Zortrax 3D printer. It is compatible with the most popular CAD/CAM software solution. Zortrax Inskpire can also work with third-party slicers.

Zortrax Inkspire works with a range of dedicated resins. Third-party photopolymers are fully supported, provided they can be cured by light with a 405 nm wavelength.

Zortrax Resin BASIC

Zortrax Resin BASIC is an epoxy-based resin offering sharp edges, high detail, and short curing times. It's durable and easy to print. Zortrax Resin BASIC is available in grey, white, and pigment free.

Zortrax Resin PRO

Zortrax Photopolymer Resin PRO offers the same sharp edges, high detail, and short curing times as Zortrax Resin BASIC, but has improved resistance to bending and impacts. It's available in black.

Zortrax Resin FLEXIBLE

Zortrax Resin FLEXIBLE is an elastic, epoxy-based resin which is highly impact resistant. Offers smooth surfaces, high level of detail, and sharp edges. Its shore hardness stands at 60 D and its elongation and break amounts to 19%.