How 3D printing improves prototyping in automotive and aerospace industries

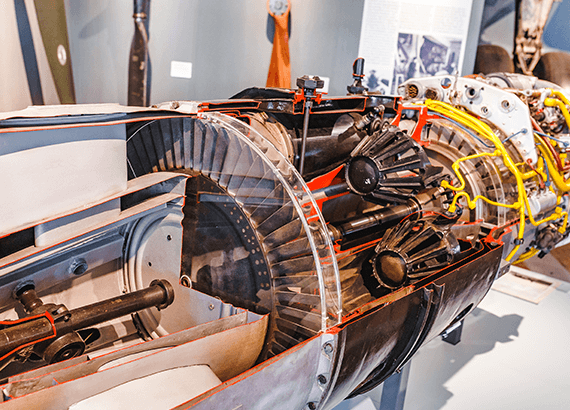

A prototype jet engine model with 3D printed elements.

In automotive and aerospace prototyping, large companies and startups alike face three major challenges

-

Parts of prototype automobiles, airplanes, or spacecraft are one-offs which are expensive and difficult to make

-

Outsourcing the fabrication of prototypes poses a risk to intellectual property protection

-

Multiple prototypes are made before the final design is agreed upon by all stakeholders

In-houseprototyping

Modern desktop 3D printers are easy to use, so the fabrication of prototypes can be performed in-house with no third-parties involved.

On-the-fly adjustments

The design of each particular part can be quickly adjusted when necessary without causing significant delays to the project.

No tooling costs

A 3D printer can print parts of almost all imaginable shapes, so there are no tooling costs each time a new design goes into fabrication.

Wide range of materials

Modern 3D printers can work with a wide variety of filaments designed to imitate materials like wood, glass, or carbon fiber.

Workflow in automotive and aerospace prototyping

Automotive and aerospace prototyping with 3D printers is done in four steps.

Step 1: CAD design

A new part is designed in CAD software.

Step 2: Choice of material

The filament is chosen based on the part's purpose.

Step 3: Fabrication

The part is 3D printed and post-processed if necessary.

Step 5: Testing

Prototypes are used for concept evaluation or functional testing.

Step 4: Assembly

3D printed parts are installed in the prototype.

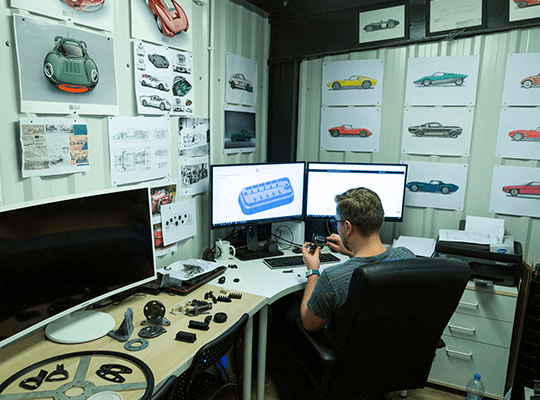

Step 1: CAD design

A new part is designed in CAD software.

Step 2: Choice of material

The filament is chosen based on the part's purpose.

Step 3: Fabrication

The part is 3D printed and post-processed if necessary.

Step 4: Assembly

3D printed parts are installed in the prototype.

Step 5: Testing

Prototypes are used for concept evaluation or functional testing.

Functional automotive prototypes

Specific parts in functional automotive prototypes can be made on 3D printers. Plastic elements of the chassis in the Falectra electric motorbike prototype have been 3D printed to match with the inventor's design idea.

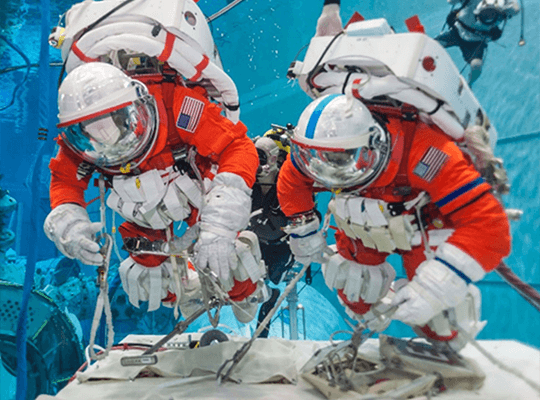

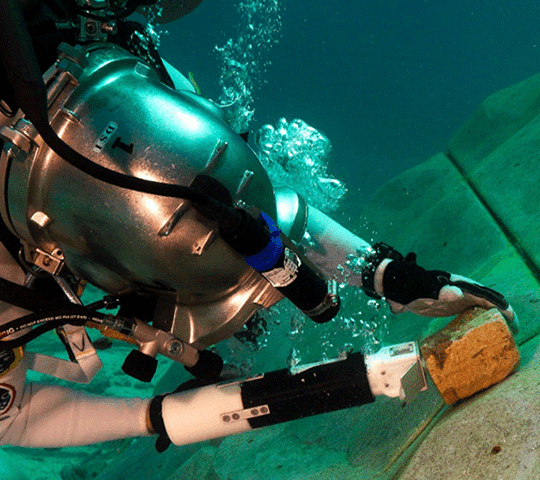

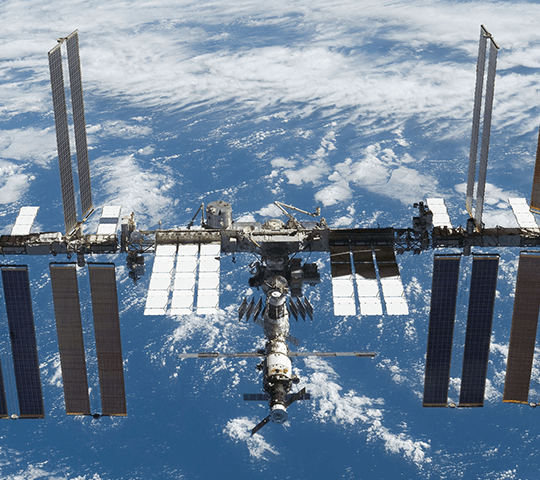

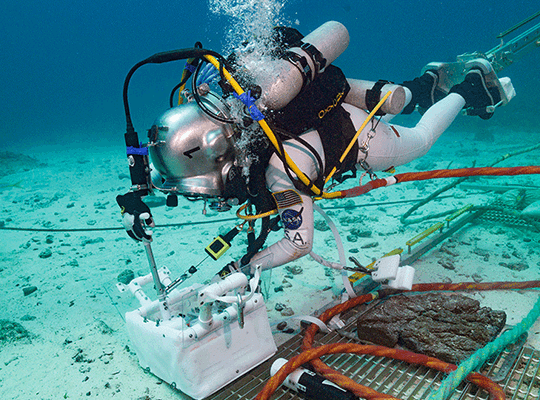

Prototyping at NASA

NASA engineers at the Johnson Space Center in Houston, Texas, use 3D printers to prototype tools for astronauts working on the International Space Station. The same team also works on equipment that is to be used on a manned asteroid redirect mission. The functional prototypes 3D printed for this project have already been tested at the NASA's NEEMO underwater research facility.

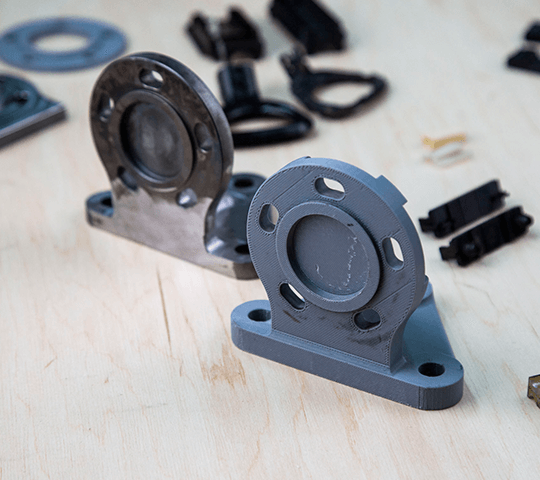

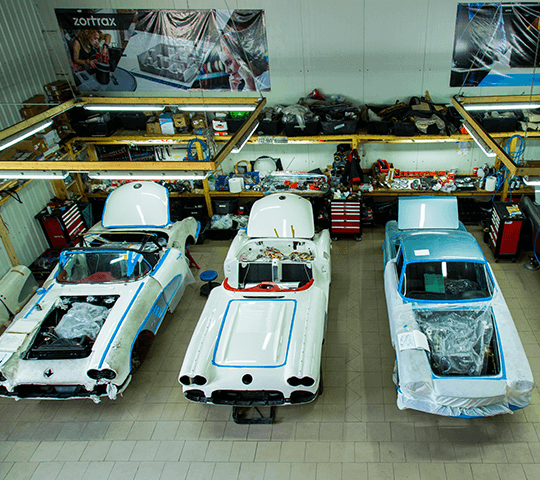

Classic car restoration

Lack of original parts is one the challenges faced by businesses doing classic car restorations. A design of a specific, unavailable part has been recreated based on old photographs of the vehicle. After 3D printing, the resulting model has been used to make a mold to cast the part in steel.

Technologies for automotive and aerospace prototyping

The choice of the right 3D printing technology for automotive or aerospace applications depends on the parts' size and purpose.

Small size parts with complex geometry

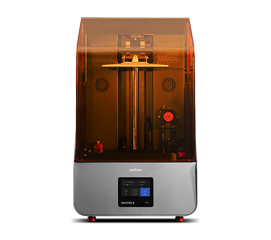

Resin 3D printing technologies like the Zortrax UV LCD are best for fabricating small yet complex parts like housings for electronics or interior details.

See more

Medium size parts with simple geometry

LPD technology is the most cost-efficient for manufacturing simple medium size parts like custom tools for astronauts on the ISS.

See more

Medium size parts with complex geometry

LPD Plus technology is best for intricately designed, medium size parts like movable elements of engines.

See more

Parts with looks of injection-molded products

SVS automated post-processing devices can be used with LPD or LPD Plus printers to manufacture parts with superior aesthetics.

See moreOur Users stories

Read more about the impact 3D printing technology has on businesses that have implemented it already.